Top 6 Considerations for Buying an AC Condensate Pump

Are you looking to buy AC condensate pumps for your home? Wondering what is necessary to consider when buying the same? If yes, then this article is for you.

When it comes to selecting an AC condensate pump, you may have a lot of options. All this can make things tricky, especially if you don’t have an idea about it.

That’s why you must consider points like features, brands, prices, and varieties when purchasing AC condensate pumps. Besides that, it also depends on your needs and budget.

Here’s a brief on things that are crucial to consider when buying AC condensate pumps:

What are AC Condensate Pumps?

AC Condensate pumps are a type of pump that helps to pump the water or condensate that is produced after the cooling of the air conditioner. The air conditioner works by a simple working principle, responsible for absorbing warmth and humidity from your place. It eventually removes the moisture, resulting in water droplets. In such cases, as the water level rises, the pump pushes the water out from the home and passes it to the condensate lines.

How to Choose the Right AC Condensate Pumps?

To choose the right AC condensate pumps, you must consider the following things:

Identifying Air-conditioning Unit Type

It is crucial to recognize the type of cooling system as it largely decides the suitable condensate pumps for your use. First, start by choosing the air-conditioning unit type, like the split, ducted, floor-mounted, or cassette. As there are various units to choose from, take your time to identify them as per your requirement.

Cooling Capacity of the Air-conditioner

Once you have identified the air-conditioning unit, decide on the cooling capacity of the same. You will be able to locate the AC cooling capacity on your AC specifications. It denotes the amount of condensate discharged per hour.

Note that if there is an AC with a large cooling capacity, the amount of condensate will be more. So, do the math as per your requirements.

Climate

Next, consider the climate and location to buy suitable AC condensate pumps. The discharge from humid climate conditions differs from dry ones. In fact, in humid conditions, the condensate could be doubled. So, you will have to get your pumps accordingly.

Installation Preference

You must also decide your installation preference, where you have to identify where the condensate pumps will be mounted. You can set the AC condensate pumps beside the unit, below the unit, inside the unit, or above the unit.

Maintenance and Cleaning

Maintainance and cleaning imply the durability of the pumps. That’s why you should consider both maintaining and cleaning the pump, pipes, and detection units. Note that some pumps could be tough to clean or detach. So read through the reviews and decide accordingly.

Brand

Lastly, you should also consider the leading brand to buy the right condensate pumps. Looking for a pump company with relevant features, durability, certification, energy-saving capabilities, operations, and performance is recommended.

Benefits of AC Condensate Pumps

AC condensate pumps offer the following benefits:

- Energy saving and efficient

- Helps to collect and transfer condensate back into the steam system for reheating and reuse

- Reduce costs related to steam production

- Simple to use, reasonable cost

- Sturdy construction

- Durable

About Condensate Pumps

Today’s pumping industry has the best-in-class condensate pumps that are sourced from top-notch brands. This includes names like Burk, Hartell, Hoffman, Liberty, Little Giant, Red Lion, and Zoeller. All these brands have dominated the industry with the best-in-class products secured with fantastic features and specifications.

The best thing about condensate pumps from these brands is that they are designed to perfection. They can remove condensate water from AC, which (otherwise) isn’t possible through gravity. They are also created to deliver high-end performance and have been in the industry for a long time.

Being highly acclaimed, pumps manufactured by these brands are robustly designed so you can get the best out of them. Also, the best thing about these brands is that they meet all the considerations for high-quality condensate pumps.

The pumps match the installation preferences, and it’s quite easy to maintain and clean. Pump Products proudly houses AC condensate pumps from these brands. To brief up about the brands:

Burk: Burk is a brand of Crane pumps & systems, a world-class manufacturer of pumps, accessories, and services.

Hartell: Started in 1962, Hartell offers the best condensate pumps that have passed the test of time so customers can stay at peace with their products

Hoffman: Hoffman pumps are leading manufacturers of condensate pumps with cast iron structures and long-term warranties against any damages. They are best-in-class and are likely to dominate the industry with their services/products.

Liberty: Liberty is headquartered in Bergen, NY, and is a leading producer of pumping products for groundwater, wastewater, commercial, and residential purposes.

Little Giant: Little Giant started off in 1962 with the need to solve a problem. The brand came a long way in 2021, with more varieties in the pumps and related products.

Red Lion: Red Lion is a global leader in the development and manufacturing of innovative pumps and accessories like sump, sewage, clean water, effluent, etc.

Zoeller: Zoeller is the foremost manufacturer of residential and commercial pumps/accessories to ensure the best solution for moving wastewater, effluent, and condensate requirements.

Pump Products

Looking for the best AC condensate pumps for your use? Check out the Pump Products catalog. The website offers the most high-quality condensate pumps with best-in-class features and performance. For more details, you can place your orders or connect with our professionals at 18004290800.

What You Need to Know- Grinder Pumps

Are you noticing an increase in sewer backups, pump breakdowns, and overflows caused by blocking? You’re not alone because it has become one big issue. Well, it takes a lot of work to instruct and make everyone sewage friendly. So, how to deal with this problem which has evolved common in multi-story residential buildings, commercial and industrial pcs.

Fortunately, easy-to-install, effective, and reliable grinder pumps can solve this problem instantly. The grinder pumps have strong cutting blades that grind the wastewater into a fine slurry, easily flowing down the long lines. Moreover, the grinder pumps also process hard solids and solve all the potential backup situations forever.

The one-time installation, versatile ranges, and durability make it one of the best investments, which is very beneficial. So, whether residential or commercial, grinder pumps can solve every problem.

Benefits of Grinder Pumps

Here are some amazing benefits of grinder pumps:

It Treats all Types of Waste

Determining what’s flushable and drainable is a tough choice. But, with the help of strong blades and multiple processing mechanisms of grinder pumps, you can treat every kind of wastewater. It effectively brings down everything to liquid. This helps to solve accidental clogging and lots of trouble.

It Takes up Less Space

Grind pumps are handy, portable, and very flexible. Moreover, it requires smaller pipes to connect to the sewage line and a smooth installation. All these characteristics make the working and setup very easy. Furthermore, you can install it in a basin or septic tank as per your choice.

It Great for Terrain

Natural gravity sewers mess up the natural terrains and impact them badly. But grinder pumps have great power to move the liquid rapidly, following the landscape. It’s great for the environment and makes it a smart choice.

It can be Used in Various Situations.

Grinder pumps are great for low-elevation houses and long-distance sewage lines if the city’s main is pressurized or your commercial place produces lots of wastewater. This makes it quite versatile for treating wastewater.

How Do Grinder Pumps Work?

Grinder pumps are generally installed using small diameter pipes, typically 1-1/4 inch to 2 inches along the basin. Also, one can install a basin (or tank) built in a suitable outdoor area. It connects the sewage from water from all the sinks and bathrooms.

Here’s a detailed working of grinder pumps:

- The premium and speed blades grind up the incoming sewage in the wastewater.

- Then, external force pushes the wastewater to the main city sewer line.

- It works for a few minutes and shuts down automatically when there’s no water to treat.

Also, some grinder pumps have a switch alarm to notify of any clogging problem. Some of the best grinder pumps in the market are Barner’s grinder pumps, Liberty grinder pumps, Franklin grinder pumps, Zoeller Grinder pumps, and much more.

Tips to Maintain your Grinder Pumps

As a responsible homeowner, you must practice some tips for the longevity of the grinder pumps. A little care and checks can go a long way and help the machine to carry the process effortlessly:

- Always examine the oil level to ensure it is sufficient; this will add life to your machine

- Check the septic grinder pump motor chamber for contaminations

- You must frequently check the pump impeller and body for excessive buildup and clean it after some time.

- Always check the grinder pump seal to avoid possible leaks.

Also, many homeowners, commercial space owners, and workers assume that after installing a grinder pump, you can throw anything in flush and sewage lines. Grinder pumps effectively break down all the solids, but being responsible about what not to throw will aid its life.

Excessive solid waste will lead to contamination, clogging, less efficiency, and short life. So avoid dumping:

- Cooking oil, grease, or fat

- Hair

- Newborn wipes

- Sanitary products

- Dental floss

- Fireplace ashes

- Cat waste

- Cigarettes or cigarette butts

- Flammable fluids or materials

Pump Products

Are you wondering how to find the best grinder pumps for your home or commercial needs? If yes, then Pump Products has got your back.

We deliver to all the addresses in the USA and initiate quick delivery once you place the order. Even if we don’t have a particular product in our inventory, we talk to suppliers and offer doorstep delivery to you.

Moreover, we believe in giving all the solutions to our customers related to various pumps, motors, spare parts, and accessories. We deal with all popular brands like AMT, Apache Hoses, Liberty, Myers, Franklin, Davey, Hoffman, etc. We will listen to your requirements and suggest the best option for you.

All this availability of products, quick delivery, and assistance make us the largest and best suppliers of the pump, electric motors, and generator industry.

For more information, you can also call us at 1-866-551-2592. We are available 24*7 for our valuable customers!

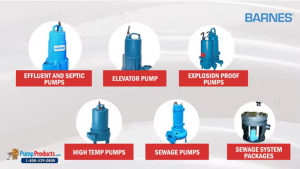

Top-Selling Brands of Explosion Proof Pumps | AMT, Barnes

Explosion proof pumps are used in hazardous environments like oil rigs, mines, and chemical plants. Pumps like AMT explosion proof pumps enclose around motors and vulnerable parts of the pump. The insulation prevents combustible elements from triggering vapor and causing external or internal explosions. The areas where explosion pumps are placed are defined by the National Fire Protection Association and the National Electric Code.

Since there are several plumbing applications where an explosion might occur, Barnes explosion proof pumps can take several forms. For instance, there are explosion proof sump pumps, explosion proof transfer pumps, and even explosion proof submersible pumps.

Features and benefits of explosion proof pumps

Explosion proof pumps are built to high standards. This pump type prevents sparks from occurring in flammable and hazardous environments where explosions are likely. Explosion proof pumps are cast with a thick outer covering. The external enclosure is so strong that it can withstand any internal mishaps that might cause an outward force during operation. They also have stringent motor winding standards. It works on preventing ignition effects that may spread from the internal to the external atmosphere. Lastly, the interfaces are created to control gas expansion in such a way that cools it before letting it safely exit through flame-prevention paths.

The type of water and how the space is classified determine when to use an explosion proof pump. In most wastewater applications, these are the preferred type of pump because the gasses that permeate the wastewater cannot set off an explosion.

Barnes explosion proof pumps are useful in industrial water uses as well, such as chemical, cleaning, or oily fluids. With most stormwater and clean water scenarios, explosion proof pumps are not used or required. The designation given for a hazardous environment by the NEC may require the implementation of an explosion proof pump in the pump station. In most scenarios, these areas are labeled as Class 1 or Division 1. Sometimes they’re also given the designation of ‘zone’. Apart from these situations, there are additional scenarios where an explosion proof pump might be necessary. When installing these specialty pumps, they must be grounded and bonded according to necessary safety codes.

Barnes Explosion Proof Pumps

The Barnes series of underwater grinder pumps are ideal for high flow, wastewater grinding uses seen in light industrial, commercial, and municipal environments. The Barnes XGV series offers long-lasting durability and easy maintenance. Barnes explosion proof pumps are designed with the revolutionizing Barnes scilerator radial cutting tech. They have an oil-filled motor and plug-and-play “Quick Connect” cord.

These pumps are the best solution for high flow, high head applications involving the use of difficult solids such as ropes, cloth materials, diapers, and plastics. Barnes explosion proof pumps are used in refineries and petrochemical. These pumps convert different types of sewage into a fine slurry. The company creates different types of explosion proof pumps such as dynamic pumps, centrifugal pumps, positive displacement pumps, rotary pumps, and specialty pumps.

An example of Barnes explosion proof pumps is their Blade Grinder series. They are efficient at high head flow waste. These pumps are available in 3HP-15HP. These pumps are designed for easy maintenance and durability.

AMT Explosion Proof Pumps

AMT Pumps are chemical, electric motor-driven pumps are meant for hazardous duty. AMT created these centrifugal pumps in stainless steel and cast iron. Also called EXP pumps, they are self-priming and end suction designs. AMT explosion pumps vary in size range from 1.2HP-15HP.

AMT explosion proof pumps are installed in industries involving pumping solvents, chemicals, or other liquids with a low flash point which needs EXP machinery. Some features of AMT explosion proof pumps are:

- Sealed with Ni-resist and carbon faces

- Can withstand temperature up to 160˚ F

- Has a maximum flow of 128 GPM

- 1-1/4″, 1-1/2″ and 2″ NPT port sizes

- 1/2 to 2 HP Single and Three (3) Phase 3450 RPM motors.

AMT pumps are a subsidiary of Gorman-Rupp. These pumps are self-priming, explosion-proof, centrifugal pumps that can be used in any environment that has flammable liquids or hazards. All the models are capped with Viton®* seals. This enables the pump to handle liquids at high temperatures.

Pump Products

PumpProducts is your ultimate, one-stop destination for purchasing AMT and Barnes explosion proof pumps. Our expert team will provide the necessary information about our selection of pump models. They will help you choose the right pump for your requirements. If you’re considering AMT explosion proof pumps, then check out the link for more information. PumpProducts is committed to supplying customers with the best quality pumps, controls, electric motors, and parts in the market at competitive prices.

In Need of a New Circulator Pump?

Having a reliable circulator pump is essential to the smooth functioning of your heating or cooling system. If you’re looking for a new, premium-quality circulator pump, then look no further than Wilo Circulator Pumps and Taco Circulator Pumps. Both these circulator pump brands are reputed for their premium quality, durability, features, and affordability. In this article, we’ll explore Wilo Circulator Pumps and Taco Circulator Pumps in greater detail.

But first, let’s understand what a circulator pump is.

What are Circulator Pumps?

Circulator Pumps, such as Wilo Circulator Pumps and Taco Circulator Pumps, are a type of centrifugal pump. They help keep a consistent circulation of liquids or gasses inside a hydraulic heating or cooling system. In some applications, a circulator pump may even circulate slurry or other materials as needed. It is often a pump that is added to the water system of residential and commercial properties. Through the circulator pump’s efficient working, hot or cold water is easily available at every faucet across the property.

Circulator pumps are imperative to keep your home or office space at the right temperature and also well-supplied with hot and cold water. If you’re interested in either replacing an old circulator pump or installing a new one, consider Wilo Circulator Pumps and Taco Circulator Pumps.

Features and benefits of Wilo Top S Series

Wilo Circulator Pumps are a highly popular circulator pump brand. The Top S Series of Wilo Circulator Pumps, in particular, is excellent for commercial and industrial applications that require heavy-duty work. It’s a great choice for a pump because:

- It can be attached and assembled to any hot water system and cooling circuits across industries.

- It is compact and can be installed with ease.

- It is not noisy and is ideal for spaces requiring a quiet pump.

- It is coated using the Cataphoresis method, which reduces the risk of corrosion.

- It can handle temperatures between 14°F and 248°F (-10°C and 120°C).

- It boasts of H Protection Class.

In the Wilo Circulator Pumps Top S Series, you’ll find the following two models the best candidates for your new circulator pump:

Wilo 2067542

The Wilo 2067542 is a cast iron pump that comes with a Cataphoresis coating that protects it from corrosive materials. It’s an excellent pump because:

- It can operate at 2 different speeds, at the same voltage of 115 volts.

- It has a premium-quality aluminum electrical box casing.

- It has a 2-bolt flange that is 1.25″ in size.

- It can support glycol and water concentration up to 50% without getting damaged.

- It can be used for a variety of applications, including the generation of geothermal or solar power.

Wilo 2067588

Next, we have the Wilo 2067588 model from the Wilo Circulator Pumps Top S Series. It is powerful and is a 3-phase circulator pump that has the following features:

- It is a 2-speed pump that runs on 208/230 volts and 1-3/4 HP.

- It has a cast iron construction with certain parts made of premium-grade cast aluminum.

- It comes already vented and is very easy to maintain.

- It has a unique thermal overload sensor that protects the pump from overheating.

- It is highly durable, made using cast aluminum and iron that is Cataphoretic coated, metal-infused carbon, stainless steel shaft, and an impeller made of composite material.

Features and benefits of Taco 008 Series

Another circulator pump brand for you to evaluate is Taco Circulator Pumps. The Taco 008 Cartridge Circulator series from Taco Circulator Pumps is a heavy-duty pump that is perfect when you want a circulator pump for every day, high-intensity usage. It is suitable for all residential, commercial, and industrial applications due to the following reasons:

- Its parts are field serviceable, and you won’t have to dismantle the entire set-up during maintenance.

- The design has a self-lubricating feature that ensures the pump always works seamlessly.

- It is available both in bronze and cast iron.

- Its compact design can support a high output at low power consumption.

- It comes with optional sweat connections.

In the Taco Circulator Pumps Taco 008 Cartridge Circulator series, you’ll find the following two models worth taking a look at:

Taco 008-F6-3IFC

The Taco 008-F6-3IFC comes with a cast iron construction that is highly durable. It also boasts of the following features:

- It operates on 115volts at 1/25 HP.

- It is built with an Integral Flow Check that minimizes installation and maintenance efforts.

- It is available with a flange-to-flange warranty for 3 years.

- Its precision technology has on-site serviceable parts.

- It does not have a mechanical seal and is self-lubricating.

Taco 008-ZSF6

Another model in the Taco Circulator Pumps Taco 008 Cartridge Circulator series is the Taco 008-ZSF6 model. It is liked by many businesses because:

- It has a reliable stainless-steel body that runs on 1/25 HP and 115 volts.

- It is designed with a Priority Zoning circulator, making it a state-of-the-art pump.

- It has moving parts and an easy-to-replace cartridge slot.

- It can support various industrial applications from in-floor heating to water recirculation systems.

- It comes with a 3 years flange-to-flange warranty.

Wilo overview

Wilo Pumps is a reputed European manufacturer of pumps and pump systems based in Germany. Wilo Circulator Pumps have been used in commercial, industrial and domestic applications for decades.

Taco overview

Taco Pumps is a family-owned American business that specializes in pumps, pump systems and replacement parts. Taco Circulator Pumps have supported many American homes and offices with their precision technology for years.

PumpProducts overview

PumpProducts.com is a reputed online distributor of pumps, motors, and pumping accessories. We can deliver premium-quality Wilo Circulator Pumps and Taco Circulator Pumps to your destination at highly affordable rates.