Top-Selling Brands of Explosion Proof Pumps | AMT, Barnes

Explosion proof pumps are used in hazardous environments like oil rigs, mines, and chemical plants. Pumps like AMT explosion proof pumps enclose around motors and vulnerable parts of the pump. The insulation prevents combustible elements from triggering vapor and causing external or internal explosions. The areas where explosion pumps are placed are defined by the National Fire Protection Association and the National Electric Code.

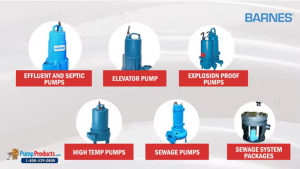

Since there are several plumbing applications where an explosion might occur, Barnes explosion proof pumps can take several forms. For instance, there are explosion proof sump pumps, explosion proof transfer pumps, and even explosion proof submersible pumps.

Features and benefits of explosion proof pumps

Explosion proof pumps are built to high standards. This pump type prevents sparks from occurring in flammable and hazardous environments where explosions are likely. Explosion proof pumps are cast with a thick outer covering. The external enclosure is so strong that it can withstand any internal mishaps that might cause an outward force during operation. They also have stringent motor winding standards. It works on preventing ignition effects that may spread from the internal to the external atmosphere. Lastly, the interfaces are created to control gas expansion in such a way that cools it before letting it safely exit through flame-prevention paths.

The type of water and how the space is classified determine when to use an explosion proof pump. In most wastewater applications, these are the preferred type of pump because the gasses that permeate the wastewater cannot set off an explosion.

Barnes explosion proof pumps are useful in industrial water uses as well, such as chemical, cleaning, or oily fluids. With most stormwater and clean water scenarios, explosion proof pumps are not used or required. The designation given for a hazardous environment by the NEC may require the implementation of an explosion proof pump in the pump station. In most scenarios, these areas are labeled as Class 1 or Division 1. Sometimes they’re also given the designation of ‘zone’. Apart from these situations, there are additional scenarios where an explosion proof pump might be necessary. When installing these specialty pumps, they must be grounded and bonded according to necessary safety codes.

Barnes Explosion Proof Pumps

The Barnes series of underwater grinder pumps are ideal for high flow, wastewater grinding uses seen in light industrial, commercial, and municipal environments. The Barnes XGV series offers long-lasting durability and easy maintenance. Barnes explosion proof pumps are designed with the revolutionizing Barnes scilerator radial cutting tech. They have an oil-filled motor and plug-and-play “Quick Connect” cord.

These pumps are the best solution for high flow, high head applications involving the use of difficult solids such as ropes, cloth materials, diapers, and plastics. Barnes explosion proof pumps are used in refineries and petrochemical. These pumps convert different types of sewage into a fine slurry. The company creates different types of explosion proof pumps such as dynamic pumps, centrifugal pumps, positive displacement pumps, rotary pumps, and specialty pumps.

An example of Barnes explosion proof pumps is their Blade Grinder series. They are efficient at high head flow waste. These pumps are available in 3HP-15HP. These pumps are designed for easy maintenance and durability.

AMT Explosion Proof Pumps

AMT Pumps are chemical, electric motor-driven pumps are meant for hazardous duty. AMT created these centrifugal pumps in stainless steel and cast iron. Also called EXP pumps, they are self-priming and end suction designs. AMT explosion pumps vary in size range from 1.2HP-15HP.

AMT explosion proof pumps are installed in industries involving pumping solvents, chemicals, or other liquids with a low flash point which needs EXP machinery. Some features of AMT explosion proof pumps are:

- Sealed with Ni-resist and carbon faces

- Can withstand temperature up to 160˚ F

- Has a maximum flow of 128 GPM

- 1-1/4″, 1-1/2″ and 2″ NPT port sizes

- 1/2 to 2 HP Single and Three (3) Phase 3450 RPM motors.

AMT pumps are a subsidiary of Gorman-Rupp. These pumps are self-priming, explosion-proof, centrifugal pumps that can be used in any environment that has flammable liquids or hazards. All the models are capped with Viton®* seals. This enables the pump to handle liquids at high temperatures.

Pump Products

PumpProducts is your ultimate, one-stop destination for purchasing AMT and Barnes explosion proof pumps. Our expert team will provide the necessary information about our selection of pump models. They will help you choose the right pump for your requirements. If you’re considering AMT explosion proof pumps, then check out the link for more information. PumpProducts is committed to supplying customers with the best quality pumps, controls, electric motors, and parts in the market at competitive prices.